耐用性好

- 坚固的铸铁和钢结构实现了较长的使用寿命

- 18:1 的滚筒直径与钢索直径最小比例,可减少钢索磨损

安全性好

- 操作杆可实现精确定位

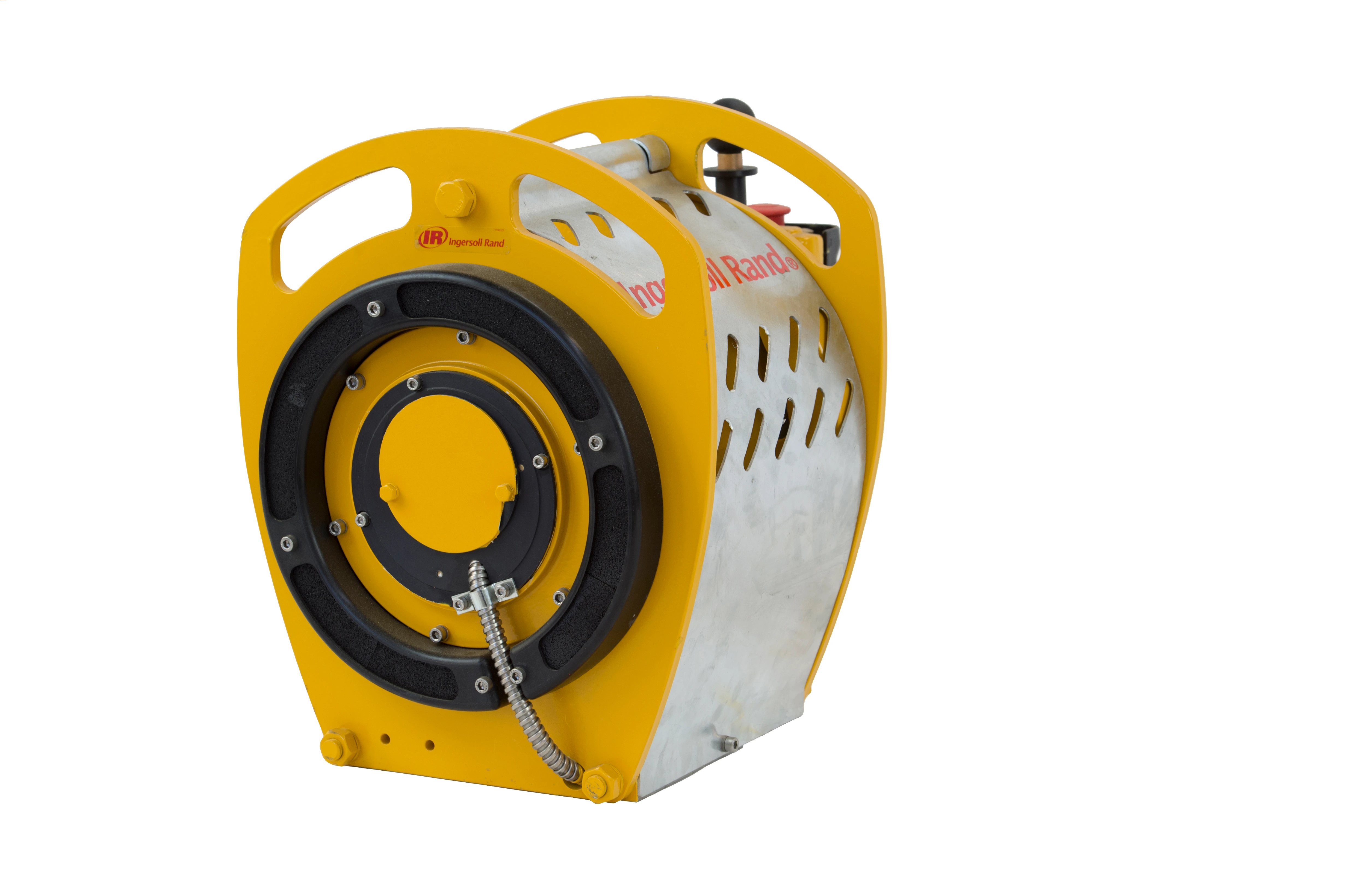

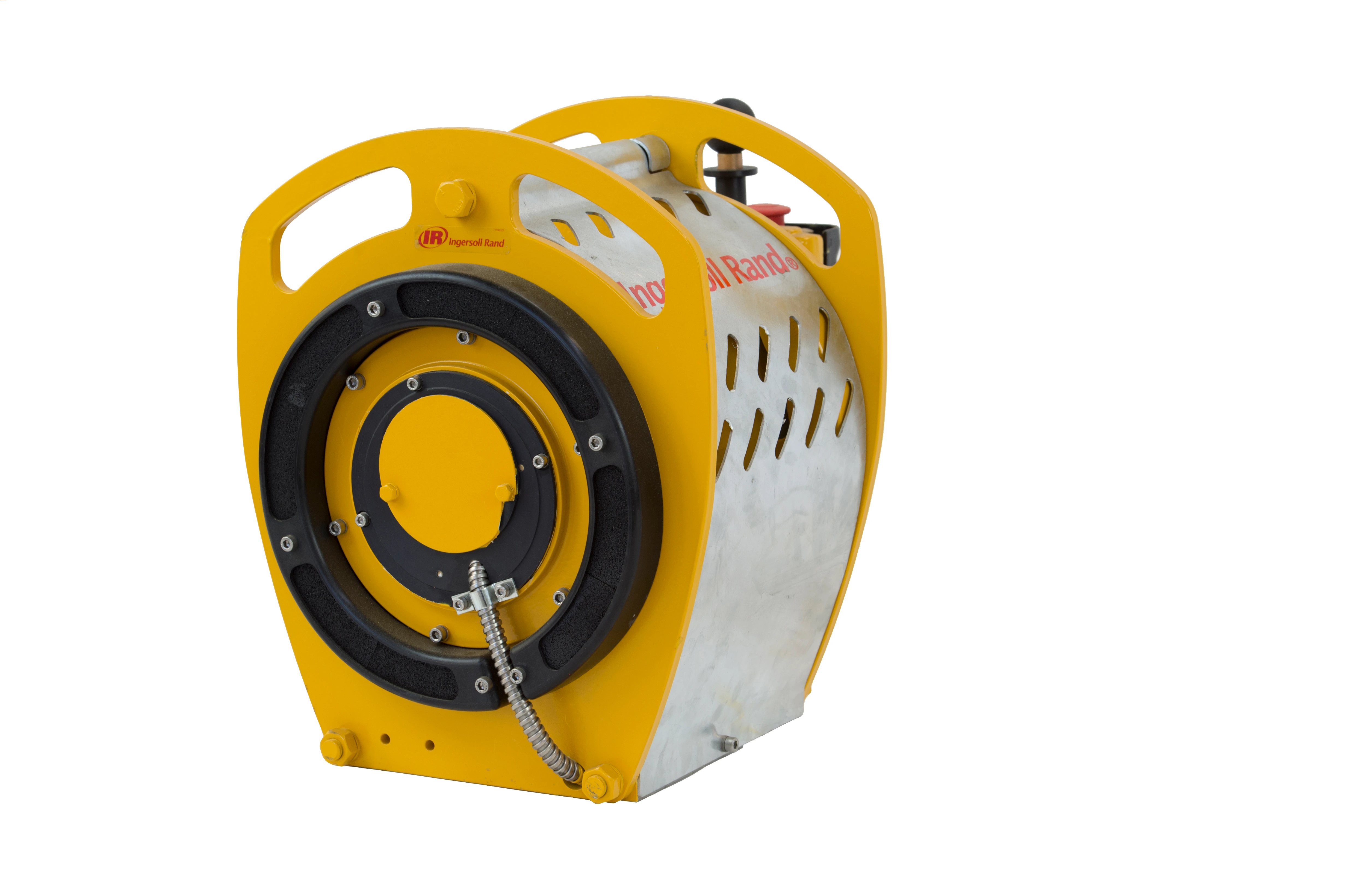

- 内置手柄和紧凑设计便于携带(便携性)

性能高

- 滚筒式齿轮箱设计减小了尺寸,使绞车适用于紧凑型应用

- 液压马达在低马达转速下提供高扭矩和高效率

- 易于配置以符合全球标准,包括 ANSI/ASME B30.7 和 CE FEM 等级 1 Bm

- 用于快速放绳的自由卷轴离合器(Pullstar 绞车)

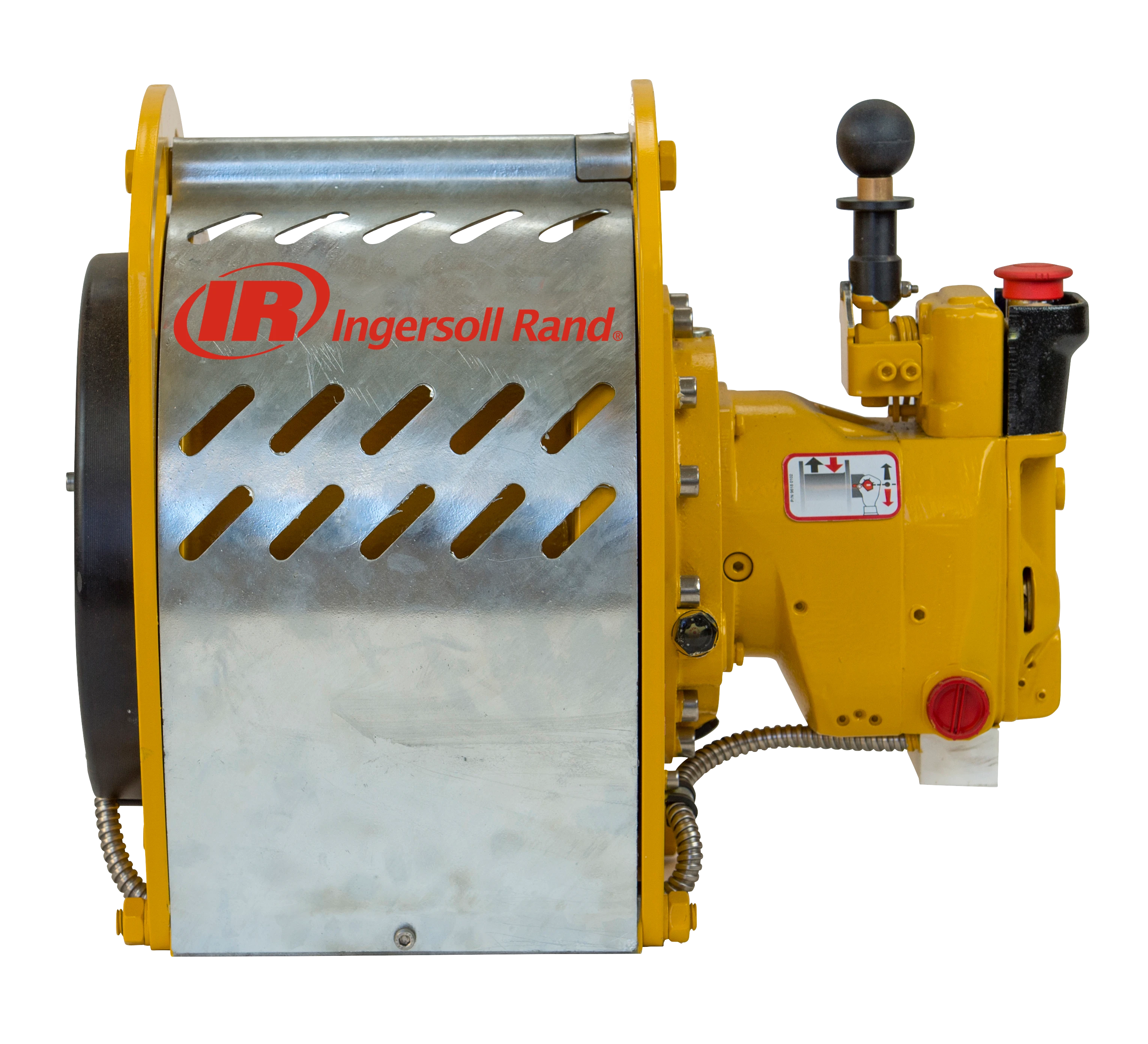

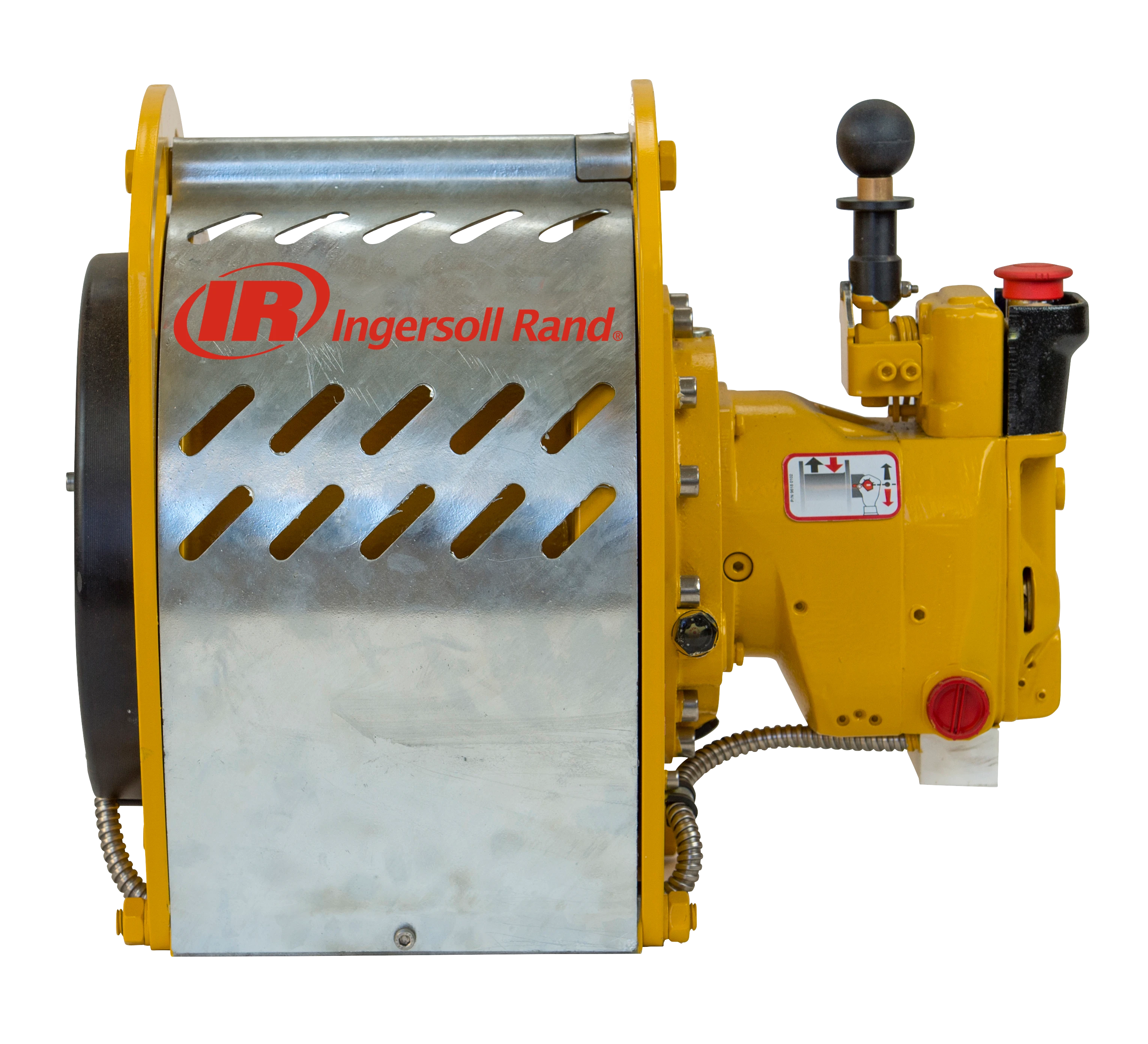

Ingersoll Rand 的 Liftstar 和 Pullstar 液压绞车具有坚固的结构,适用于您为其分配的任何起重作业或应用。这些绞车配备了可靠的液压马达,具有便携性和强大的起重能力。Liftstar 绞车设计用于起重应用,而 Pullstar 绞车设计用于牵引应用。Liftstar 和 Pullstar 液压绞车由封闭式齿轮箱提供保护,其铸铁和钢结构经久耐用,可确保您的生产运行多年。

耐用性好

安全性好

性能高

| Model | LS2-300R-L | LS2-300RGC-L | LS2-600R-L | LS2-600RGC-L | LS2-1500R-L | LS2-1500RGC-L | PS2-1000R-L | PS2-1000RGC-L | PS2-2400R-L | PS2-2400RGC-L | LS2000R-L | LS2000RGC-L | LS5000R-L | LS5000RGC-L | PS4000R-L | PS4000RGC-L(3) | PS10000R-L | PS10000RGC-L | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Line Pull Capacity First Layer kg (lb) | 300 (660) | 300 (660) | 600 (1,320) | 600 (1,320) | 1,500 (3,300) | 1,500 (3,300) | 1,000 (2,200) | 1,000 (2,200) | 2,400 (5,280) | 2,400 (5,280) | 2,800 (6,170) | 2,800 (6,170) | 6,500 (14,330) | 6,500 (14,330) | 4,000 (8,800) | 3,600 (7,920) | 10,000 (22,000) | 10,000 (22,000) | |||||

| Line Pull Capacity Mid Drum kg (lb) | 300 (660) | 300 (660) | 600 (1,320) | 600 (1,320) | 1,500 (3,300) | 1,500 (3,300) | 850 (1,870) | 850 (1,870) | 2,150 (4,730) | 2,150 (4,730) | 2,400 (5,290) | 2,400 (5,290) | 5,750 (12,670) | 5,750 (12,670) | 3,250 (7,150) | 2,925 (6,435) | 8,740 (19,265) | 8,740 (19,265) | |||||

| Line Pull Capacity Top Layer kg (lb) | 300 (660) | 300 (660) | 600 (1,320) | 600 (1,320) | 1,500 (3,300) | 1,500 (3,300) | 700 (1,540) | 700 (1,540) | 2,000 (4,400) | 2,000 (4,400) | 2,000 (4,400) | 2,000 (4,400) | 5,000 (11,000) | 5,000 (11,000) | 2,500 (5,500) | 2,250 (4,950) | 7,500 (16,530) | 7,500 (16,530) | |||||

| Lifting/Pulling Speed at Top Layer(1) m/min (fpm) | 40 (131) | 40 (131) | 20 (66) | 20 (66) | 9.5 (31) | 9.5 (31) | 20 (66) | 20 (66) | 6 (20) | 6 (20) | 20 (66) | 20 (66) | 10 (33) | 10 (33) | 7 (23) | 8 (25) | 4 (14) | 4 (14) | |||||

| Air Consumption with Rated Load m3/min (ft3/min) | 4 (141) | 4 (141) | 4 (141) | 4 (141) | 4.8 (169) | 4.8 (169) | 4 (141) | 4 (141) | 4.8 (169) | 4.8 (169) | 10 (353) | 10 (353) | 10 (353) | 10 (353) | 12 (424) | 12 (424) | 12 (424) | 12 (424) | |||||

| Air Volume Needed to Move Rated Load at Top Layer 3 m (10 ft) | 0.3 (10.8) | 0.3 (10.8) | 0.6 (21.4) | 0.6 (21.4) | 1.5 (53.0) | 1.5 (53.0) | 0.6 (21.4) | 0.6 (21.4) | 2.4 (84.8) | 2.4 (84.8) | 1.5Model | LS2-600H40-L | LS2-600H40GC-L | PS2-1000H40-L | PS2-1000H40GC-L | LS2000H30-L | LS2000H30GC-L | LS5000H75-L | LS5000H75GC-L | PS4000H30-L | PS4000H30GC-L | PS10000H75-L | PS10000H75GC-L |

| Line Pull Capacity First Layer kg (lb) | 800 (1,750) | 800 (1,750) | 1,000 (2,200) | 1,000 (2,200) | 2,800 (6,200) | 2,800 (6,200) | 6,500 (14,330) | 6,500 (14,330) | 4,000 (8,800) | 4,000 (8,800) | 10,000 (22,000) | 10,000 (22,000) | |||||||||||

| Line Pull Capacity Mid Drum kg (lb) | 700 (1,535) | 700 (1,535) | 850 (1,870) | 850 (1,870) | 2,400 (5,300) | 2,400 (5,300) | 5,750 (12,665) | 5,750 (12,665) | 3,465 (7,620) | 3,465 (7,620) | 8,300 (18,290) | 8,300 (18,290) | |||||||||||

| Line Pull Capacity Top Layer kg (lb) | 600 (1,320) | 600 (1,320) | 700 (1,540) | 700 (1,540) | 2,000 (4,400) | 2,000 (4,400) | 5,000 (11,000) | 5,000 (11,000) | 2,930 (6,440) | 2,930 (6,440) | 7,000 (15,430) | 7,000 (15,430) | |||||||||||

| Lifting Speed at Top Layer(1) m/min (fpm) | 20 (66) | 20 (66) | 20 (66) | 20 (66) | 30 (98) | 30 (98) | 30 (98) | 30 (98) | 20 (66) | 20 (66) | 13 (43) | 13 (43) | |||||||||||

| Motor Displacement cm3/rev (in3/rev) | 40 (2.44) | 40 (2.44) | 40 (2.44) | 40 (2.44) | 30 (1.80) | 30 (1.80) | 75 (4.60) | 75 (4.60) | 30 (1.80) | 30 (1.80) | 75 (4.60) | 75 (4.60) | |||||||||||

| Operating Pressure bar (psi) | 100 (1,450) | 100 (1,450) | 120 (1,740) | 120 (1,740) | 150 (2,180) | 150 (2,180) | 150 (2,180) | 150 (2,180) | 180 (2,610) | 180 (2,610) | 220 (3,190) | 220 (3,190) | |||||||||||

| Rated Flow l/min (gal/min) | 25 (6.6) | 25 (6.6) | 25 (6.6) | 25 (6.6) | 65 (17.2) | 65 (17.2) | 142 (37.5) | 142 (37.5) | 40 (10.6) | 40 (10.6) | 75 (19.8) | 75 (19.8) | |||||||||||

| Drum Capacity(2) Rope Length m (ft) | 89 (292) | 183 (600) | 89 (292) | 183 (600) | 156 (512) | 313 (1,026) | 219 (718) | 463 (1,519) | 156 (512) | 313 (1,026) | 219 (718) | 463 (1,519) | |||||||||||

| Drum Capacity(2) Rope Diameter mm (in) | 6.5 (1/4) | 6.5 (1/4) | 6.5 (1/4) | 6.5 (1/4) | 13 (1/2) | 13 (1/2) | 20 (3/4) | 20 (3/4) | 13 (1/2) | 13 (1/2) | 20 (3/4) | 20 (3/4) | |||||||||||

| Net Weight kg (lb) | 52 (115) | 59 (130) | 52 (115) | 59 (130) | 300 (661) | 353 (778) | 730 (1,609) | 987 (2,176) | 210 (463) | 235 (518) | 550 (1,213) | 615 (1,356) (53.5) | 1.5 (53.5) | 3.0 (107.0) | 3.0 (107.0) | 5.1 (184.3) | 4.5 (169.6) | 9.0 (302.9) | 9.0 (302.9) | ||||

| Sound Level as per EN 14492-1 dB(A) | 92 | 92 | 92 | 92 | 90 | 90 | 92 | 92 | 90 | 90 | 95 | 95 | 87 | 87 | 95 | 95 | 87 | 87 | |||||

| Drum Capacity(2) Rope Length m (ft) | 150 (492) | 307 (1,007) | 89 (292) | 183 (600) | 61 (200) | 128 (420) | 89 (292) | 183 (600) | 60 (197) | 127 (417) | 156 (512) | 230 (755) | 224 (494) | 473 (1,043) | 156 (512) | 230 (755) | 224 (735) | 473 (1,552) | |||||

| Drum Capacity(2) Rope Diameter mm (in) | 5 (3/16) | 5 (3/16) | 6.5 (1/4) | 6.5 (1/4) | 11 (7/16) | 11 (7/16) | 6.5 (1/4) | 6.5 (1/4) | 11 (7/16) | 11 (7/16) | 13 (1/2) | 13 (1/2) | 20 (3/4) | 20 (3/4) | 13 (1/2) | 13 (1/2) | 20 (3/4) | 20 (3/4) | |||||

| Net Weight kg (lb) | 42 (93) | 49 (108) | 42 (93) | 49 (108) | 85 (187) | 100 (220) | 38 (84) | 45 (99) | 85 (187) | 100 (220) | 230 (507) | 283 (624) | 645 (1,422) | 760 (1,676) | 225 (496) | 278 (613) | 640 (1,411) | 755 (1,664) |

Lifting Ratings at 5:1 design factor and performance at 6.3 bar (90 psi) at air inlet when winch is operating.

Pulling Ratings at 3.5:1 design factor and performance at 6.3 bar (90 psi) at air inlet when winch is operating.

(1) Top layer speed is based on rated capacity.

(2) Wire rope is tightly wound with no freeboard.